Introduction

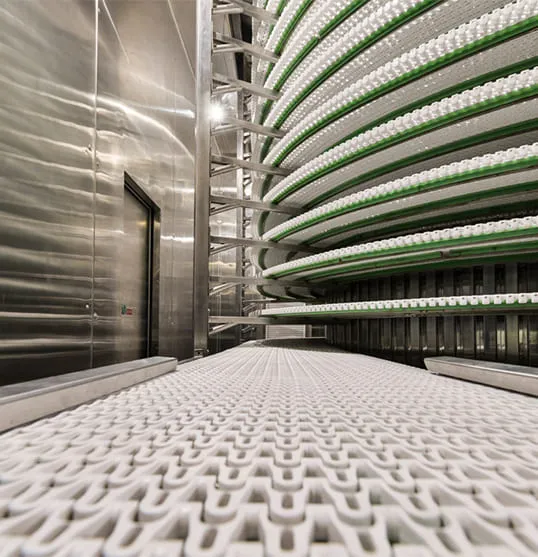

Rinac India Limited stands as a trusted leader in delivering fully integrated EPC (Engineering, Procurement & Construction) solutions for cold chain and food processing infrastructure. With over three decades of experience, Rinac specializes in designing, engineering, and executing end-to-end temperature-controlled facilities that cater to the dynamic needs of the global food, agriculture, pharma, and logistics industries, ensuring speed, hygiene, sustainability, and compliance from concept to commissioning.