Rinac India Limited offers one of the industry’s most comprehensive portfolios of cold chain solutions. We are dedicated to maintaining the integrity of temperature-sensitive goods across critical sectors like agriculture, pharmaceuticals, dairy, meat, seafood, and logistics among others. Our solutions ensure everything from fresh produce to vital vaccines is stored, processed, and transported under optimal conditions, every step of the way.

Rinac has certifications such as ISO, FSSAI, HACCP, GMP, IGBC (for green buildings), and WHO-GMP.

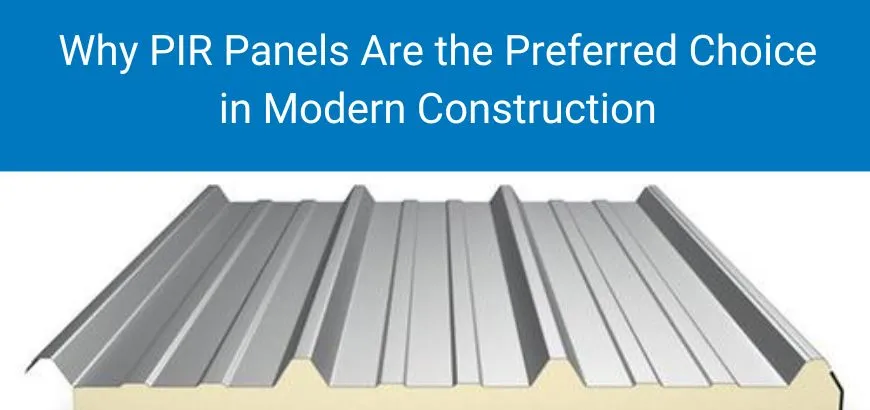

Rinac uses high-density PUF insulation, corrosion-resistant steel, food-safe coatings, and robust joining systems. Structural integrity, fire resistance, and thermal performance are validated through lab and on-site testing.

Rinac follows stringent Quality Assurance (QA) and Quality Control (QC) protocols at every stage—raw material inspection, in-process quality checks, and pre-dispatch inspection—to ensure product consistency and reliability.

Yes. Rinac’s manufacturing units are ISO 9001, ISO 14001, and ISO 45001 certified, reflecting a commitment to quality management, environmental responsibility, and occupational health and safety.

Rinac manufactures a wide range of cold chain components in-house, including PUF and PIR insulated panels, cold room doors, modular clean room panels, pre-fabricated buildings, and customized enclosures for food and pharma applications.

Rinac has state-of-the-art manufacturing plants strategically located in India, at Murbad near Pune and in Bangalore to support timely production and delivery. The key facilities are equipped to manufacture insulated panels, refrigeration components, doors, and clean room systems.

Yes, Rinac has successfully executed projects in countries across Africa, the Middle East, and Southeast Asia, with experience in handling export regulations and climate-specific customizations.

You can reach out through Rinac’s website or sales team. The process includes site survey, requirement analysis, solution proposal, detailed design, project execution, and commissioning.

Yes. Rinac offers comprehensive O&M (Operations and Maintenance) services, including AMC (Annual Maintenance Contracts),ALC(Annual Labour Contract) periodic health checks, and remote monitoring.

Rinac also provides pre-processing and processing rooms, IQF tunnels, clean modular construction for food factories, and temperature-controlled logistics support in partnership with clients.

Rinac integrates high-efficiency compressors, PUF insulation, energy-efficient lighting, and advanced controls to minimize energy consumption and improve operational cost savings.

Rinac cold rooms can support a wide range of temperatures from +15°C to -40°C, depending on the product and storage need.

Absolutely. Rinac specializes in tailor-made solutions based on the temperature, humidity, and handling requirements of specific products—be it dairy, meat, seafood, fruits & vegetables, or vaccines.

Yes, Rinac delivers turnkey cold chain infrastructure including civil works, refrigeration systems, insulated panels, doors, racking, and allied utilities – all under one roof.

Rinac offers a range of cold storage solutions including frozen storage, chilled storage, controlled atmosphere (CA) storage, modified atmosphere (MA) storage, pre-coolers, blast freezers, and ripening chambers.

Rinac offers a range of cold storage solutions including frozen storage, chilled storage, controlled atmosphere (CA) storage, modified atmosphere (MA) storage, pre-coolers, blast freezers, and ripening chambers.

Rinac offers a range of cold storage solutions including frozen storage, chilled storage, controlled atmosphere (CA) storage, modified atmosphere (MA) storage, pre-coolers, blast freezers, and ripening chambers.

Rinac is a leading provider of end-to-end cold chain infrastructure, offering design, supply, installation, and maintenance of temperature-controlled environments for perishable goods across sectors like food, pharma, and retail.