- Home

- Industry

- Dairy & Icecream Cold Chain Solutions

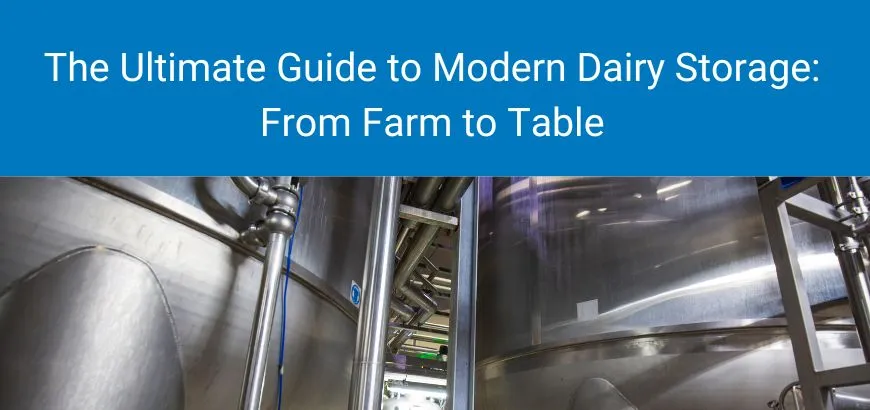

At Rinac, we understand that the dairy industry thrives on precision, hygiene, and consistency. From preserving the freshness of milk and its derivatives to ensuring seamless cold storage and transport, our innovative solutions cater to every aspect of the dairy supply chain.

With our state-of-the-art cold chain systems and clean modular construction expertise, we empower dairy producers, processors, and retailers to meet industry demands while adhering to the highest standards of quality and efficiency. Whether you need advanced storage facilities, cutting-edge process solutions, or turnkey plant setups, Rinac offers a comprehensive, tailor-made approach backed by our decades of experience and commitment to excellence.