In modular construction, insulated sandwich panels used in walls and ceilings offer superior structural stability. These sandwich panels, which are formed by covering or skinning a thermally insulated core with metal sheets, also offer some unique benefits in the construction of warehouses, factories, hotels, poultry pens, etc.

When different types of sandwich panels are available—PUF (polyurethane foam), PIR (polyisocyanurate), EPS (expanded polystyrene), etc. —the next question that arises is why PIR panels are becoming the most preferred choice in construction. So, let us discover more!

What Is PIR?

PIR or polyisocyanurate is one of the most thermally efficient insulation materials available in the industry. PIR is often described as combustible insulation, a term used for many other insulating materials. However, these materials (polyurethane/PU/PUR/EPS/XPS) do not have the properties that PIR possesses.

PIR is a thermoset polymeric material, combining isocyanates and polyols. This means it does not melt on heating. Depending on the process of manufacturing and the standard followed, the quality and performance of PIR may vary. That is why, it is important to check for the required certifications when making a choice.

What Is a PIR Panel?

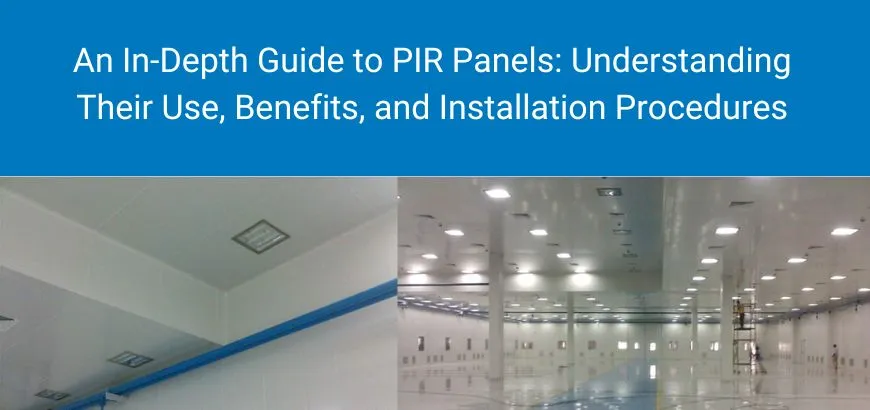

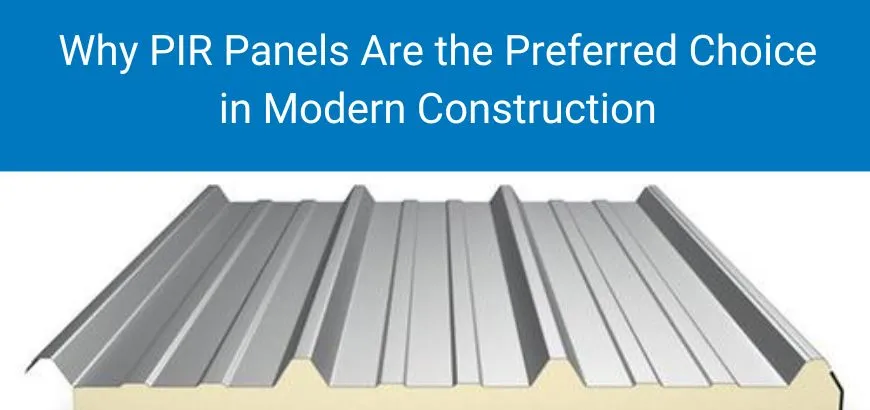

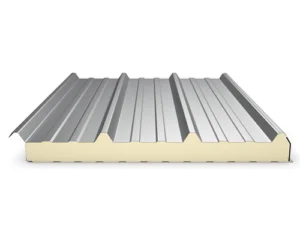

PIR sandwich panels or polyisocyanurate sandwich panels comprise three layers—high-density, rigid polyisocyanurate foam covered with coated galvanised or aluminum plates on both sides.

These PIR panels have superior heat insulation properties as well as mechanical load and and high wind speed load-bearing capacity and, thus, find application in the construction of building materials that require high fire resistance. In fact, its thermal conductivity is below 0.023 W/(m·K).

In modern construction, PIR sandwich panels are also the most effective acoustic materials.

Where Are PIR Panels Used?

PIR panels have unique properties.

- Ability to reduce heat transmission: Helps achieve maximum freezing efficiency by minimizing heat transfer between internal and external environments.

- Heat and sound insulation

- Better chemical-resistance and water-resistance properties

- Anti-corrosive and insect-free

- Easy installation

- Lightweight

- Environment-friendly

Because of the abovementioned properties, PIR sandwich panels find extensive applications in chemical industry, petroleum industry, construction of clean rooms, cold storages, warehouses, prefab buildings, and ripening chambers, packaging, cold chain and refrigeration industry, military and space industry, transportation, aviation, and others.

What Is the Difference Between PU and PIR Panels?

Rigid Polyurethane (PU) foam has been used in construction since the 1960s as a high-performance insulation material. Over the years, PIR has become the preferred choice due to its exceptional thermal insulation properties.

One of the major difference between PU and PIR sandwich panels is the fire/flame resistance property. PU foam is known has limited fire resistance and PU sandwich panel is normally produced with B2 and B3 fire classification. Whereas, PIR not only slows down the spreading of flames but also lowers smoke emission. When compared to PU, PIR panels have better fire resistance, lower combustibility, and higher working temperature range. Usually, PIR panels are produced in accordance with the B1 or B2 fire rating.

What Is the Difference Between PIR and XPS?

Both EPS (expanded polystyrene) and XPS (extruded polystyrene) are manufactured from the petroleum-based resin which is a thermoplastic based on non-cross-linked polymers. Such polymers when exposed to high temperatures melt and also get degraded in certain solvents.

PIR, on the hand hand, is a thermoset plastic which is based on cross-linked polymers that can tolerate higher temperatures and have better heat resistance. They do not melt but char at high temperatures and are also more resistance to solvents and chemicals than polystyrene.

Is PIR Panel Fire Rated?

Rinac’s PIR panles are B2-grade fire-rated and certified as CLASS ‘O’ building material in accordance with BS 476 part 6 & 7 standard.

How Can Rinac Support Your Construction Needs

Rinac offers clean modular construction options with three different types of core materials.

PUF sandwich panels

- Metal laminates made from pre-painted galvanised steel

- Low density of up to 35—40 kg/m3

- Customised finishes of aluminum, plastisol, and stainless steel

- CFC-free and high-temperature insulation

PIR sandwich panels

- Certified by ISO, OHSAS, EMS [IMS-ISO 18001 & 14001 of 2015 and OHSAS 18001/2007]

- B2-grade fire-rated PIR material

- Certified as CLASS ‘O’ building material in accordance with BS 476 part 6 & 7 standard

- Quick and easy-to-install with self-mating interlocking

- Excellent insulation as R/U values drastically reduce radiant heat transfer and condensation

FM approved sandwich panels

- In accordance with the European standard EN 14509 and ISO standards

- CFC-free high-quality polyisocyanurate (PIR) foaming material with an average density of 42 kg/m3, firmly sandwiched between the metal surfaces

- Factory-made and self-supporting

- Double skin metal faced insulated

- Exceptional fire-resistant and thermal properties

Know more about smart and durable construction solutions including InstaCeil, InstaBuild, HPCC, and Firearmet today! Speak to our experts and discover how we can support your construction needs with deep industry knowledge and technical expertise.