With conscious efforts towards environmental protection, the construction industry is making strides towards energy efficiency and sustainable construction practices. Following this trend, insulated sandwich panels have gained the attention of the construction industry with numerous commercial, economical, and environmental advantages. With its unique construction— a core insulation material sandwiched between two outer layers, these panels are transforming structural design and construction.

So, let’s dive in.

What Are Insulated Sandwich Panels?

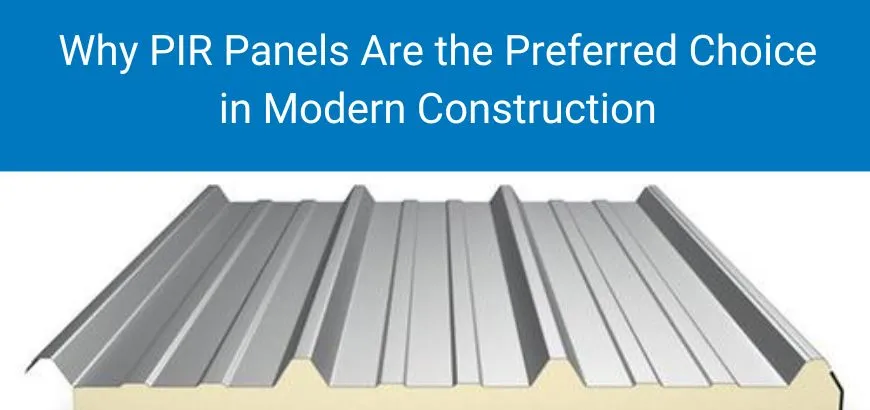

Insulated sandwich panels, also known as sandwich panels, are versatile and popular composite building materials typically used in the construction of walls, floors, roofs, and ceilings. These prefabricated building panels consist of three layers: two outer layers called facing or skins, and a core insulating material sandwiched between the layers, hence the name sandwich panels.

The outer skins can be made from various materials such as wood, steel, metal or fiber-reinforced plastic, and the core is generally made of polyurethane foam, expanded polystyrene (EPS), or mineral wool. Apart from being a modern, and light construction material, sandwich panels offer excellent thermal insulation and durability.

Installation Process of Sandwich Panels

Insulated sandwich panels have become a preferred choice across industries because of their sturdy structure and easy installation. Generally, prefabricated panels are manufactured offsite and then transported to the construction site where they’re installed using various methods such as adhesive, screws, or interlocking joint assembly (mechanical fixing).

This prefabricated property of sandwich panels helps businesses expedite construction and reduce labour costs.

Understanding the Composition and Design

With thermal and acoustic insulation and fire and water-resistant capabilities sandwich panels comprise three layers:

- Inner sheet (aka facing or skin)

- Outer sheet

- Central insulation core

The outer layer of the sandwich panels protects from external weather conditions such as temperature, moisture, and UV rays. The inner skin provides resistance from condensation and chemical gases produced by the inner atmosphere of the building. Thus, together these layers contribute to structural integrity.

The central core acts as a thermal insulator that helps regulate the temperature and reduces heat transfer.

- Facing or skin: They are generally made of metal (aluminium or steel), wood, fiberglass, or reinforced plastic.

- Core material: This is usually made of materials such as polyurethane foam (PU), expanded polystyrene (EPS), mineral wool, or fiberglass-reinforced panels (FRP).

Types of Insulated Sandwich Panels

Depending on the types of materials used for the skin and inner core, insulated sandwich panels come in different varieties.

- Polyurethane foam panels (PU): The core is made of PU foam sandwiched between metal or fiberglass facings. They are lightweight, provide excellent thermal insulation, and are suitable for a variety of external and internal applications.

- Expanded polystyrene (EPS) panels: The core is made of EPS foam with usually metal or fiberglass facing. These are cost-effective, offer good insulation properties, and are suitable for various building applications.

- Mineral wool panels: The core is made of mineral wool insulation which is derived from natural minerals such as basalt or rock wool. They provide excellent fire resistance and sound insulation properties.

- Fiberglass reinforced panels (FRP): They have fiberglass facing and the core material of usually PU foam. They’re lightweight with strong structural support and are resistant to corrosion and moisture. They are suitable for high humid environments and chemical exposure.

Applications of Insulated Sandwich Panels

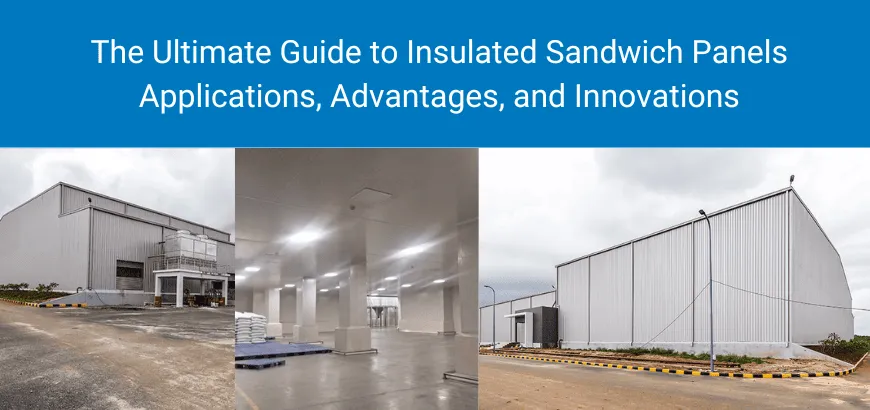

Insulated sandwich panels have applications across different industries. Here are some of the common applications.

- Industrial buildings: Factories, warehouses, and production facilities use these panels for excellent temperature control and energy efficiency.

- Commercial buildings: Sandwich panels offer superior acoustic properties and superior insulation for warehouses, logistic hubs, car showrooms, sports arenas, stadiums, recreational facilities, shopping malls, supermarkets, and retail shops.

- Residential buildings: Insulated sandwich panels prove an excellent building material for energy-efficient homes.

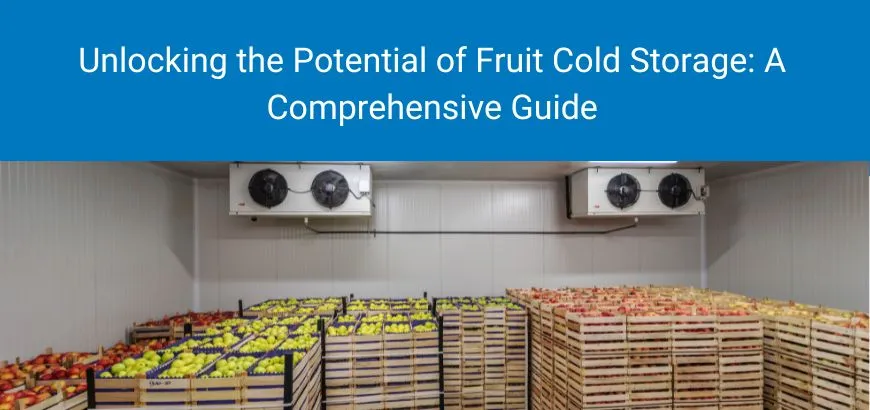

- Cold chain infrastructure: These panels are crucial for cold chain infrastructures because of their excellent heat insulation.

- Laboratories and research centers: Insulation panels help keep medical equipment cool and in good working condition by maintaining ambient conditions.

Advantages of Insulated Sandwich Panels

Insulated sandwich panels offer numerous advantages.

Fast and easy installation

Since these are prefabricated, they eliminate the need for on-site fabrication and reduce construction time. To add on, assembling these panels also doesn’t consume much resources.

Thermal insulation

Thermal insulation means reducing the energy spent in winter for warming and in summer for cooling. The panels prevent heat transmission, maintaining comfortable internal conditions. The thickness of the insulation material depends on construction requirements.

Fire resistance

Depending on the materials used, insulated sandwich panels also offer superior fire resistance properties, enhancing the safety of the building.

Acoustic performance

Insulated sandwich panels also provide sound insulation which reduces or cuts off the outside noise and provides ideal acoustic settings.

Lightweight and durable structure

These panels are comparatively lightweight yet structurally strong. They are weather-resistant and ensure long-term stability and less maintenance requirements.

Energy efficient

These panels minimize heat transfer and create a well-insulated building. This helps reduce reliance on heating, ventilation, and cooling systems and decreases energy consumption. Insulated sandwich panels thus play a crucial role in creating energy-efficient and eco-friendly buildings.

Design versatility and aesthetic appearance

The flexibility and customization of these panels give architects and builders the opportunity and freedom to explore design options.

Innovations in Sandwich Panels

Here are some ways in which sandwich panels are evolving.

- Vacuum Insulated Panels (VIP): VIPs consist of a core material enclosed within a gas-tight barrier, which is removed to create a vacuum. This results in extremely high thermal insulation properties. They are often used in applications where space is limited, such as refrigerated containers and appliances.

- Biodegradable and recyclable panels: With new technology, it is now possible to develop panels with biodegradable or recyclable materials. This can help reduce environmental impact.

- Smart panels: By integrating technology with these panels, builders can install sensors to monitor and control various building parameters such as temperature, humidity, and energy usage.

Final Words

Insulated sandwich panels are a popular choice in construction due to their advantages in terms of insulation, speed of installation, and versatility for various building applications. With an efficient installation process and cost-effectiveness, insulated sandwich panels are a smart choice for any construction project that is looking at energy and cost savings with durability and robustness.

To know more about how world-class insulated sandwich panels can transform your construction needs, get in touch with us today.