High-Performance Composite Construction (HPCC) is revolutionizing modern building techniques by combining advanced materials science with efficient construction methods. This innovative approach creates high-strength, lightweight structures that outperform traditional construction methods in durability, energy efficiency, and speed of construction.

The market for construction composites, valued at $6.3 billion in 2022, is expected to reach $10.38 billion by 2031, growing at a CAGR of 5.7%. This rapid growth highlights the increasing demand for HPCC solutions in the construction industry.

This blog explores the key advantages of HPCC, its applications in modern construction, and why it’s becoming the preferred choice for forward-thinking builders and developers.

What Makes HPCC Different from Traditional Construction?

HPCC fundamentally transforms commercial construction by integrating engineered materials that outperform conventional building methods. Unlike traditional steel or concrete construction, HPCC components—such as columns, rafters, purlins, and girts—are created using patented polymer technology and pre-coated steel.

Key Differences:

- Lightweight Yet Strong: HPCC components have a superior strength-to-weight ratio compared to steel and concrete.

- Maintenance-Free: Unlike steel, HPCC does not corrode, reducing maintenance costs.

- Customizable for Harsh Environments: HPCC structures withstand high winds, heavy rainfall, extreme temperatures, and seismic activity.

This makes HPCC ideal for commercial buildings, industrial warehouses, and institutional structures in diverse geographic regions.

Material Composition and Engineering Excellence

The core strength of HPCC lies in its advanced materials and engineering techniques.

How HPCC Works:

Composite Panels: HPCC uses Rigid Polyurethane Foam (RPUF) insulation sandwiched between Pre-Coated Galvanized Iron (PCGI) layers.

Superior Insulation: These materials offer excellent thermal efficiency, significantly reducing heating and cooling costs.

Factory-Based Manufacturing: Unlike on-site construction, HPCC components are precisely engineered in a controlled environment, ensuring consistent quality.

This modular approach results in higher durability, energy efficiency, and faster installation than traditional materials.

Quality Control and Compliance with Building Standards

One of the major advantages of HPCC is its rigorous quality control process.

- Manufacturing Standards: HPCC components are produced under strict factory conditions, ensuring compliance with international building codes.

- Multi-Stage Inspections: Both in-house and third-party agencies inspect each component for structural integrity and safety compliance.

- Reduced On-Site Variability: Unlike traditional construction, which is affected by weather, labor quality, and site conditions, HPCC ensures consistent quality.

For builders and developers, this means higher confidence in the structural reliability and long-term performance of HPCC buildings.

The Practical Benefits of HPCC in Construction

HPCC technology offers numerous practical advantages over traditional building methods.

1. Faster Construction Timelines

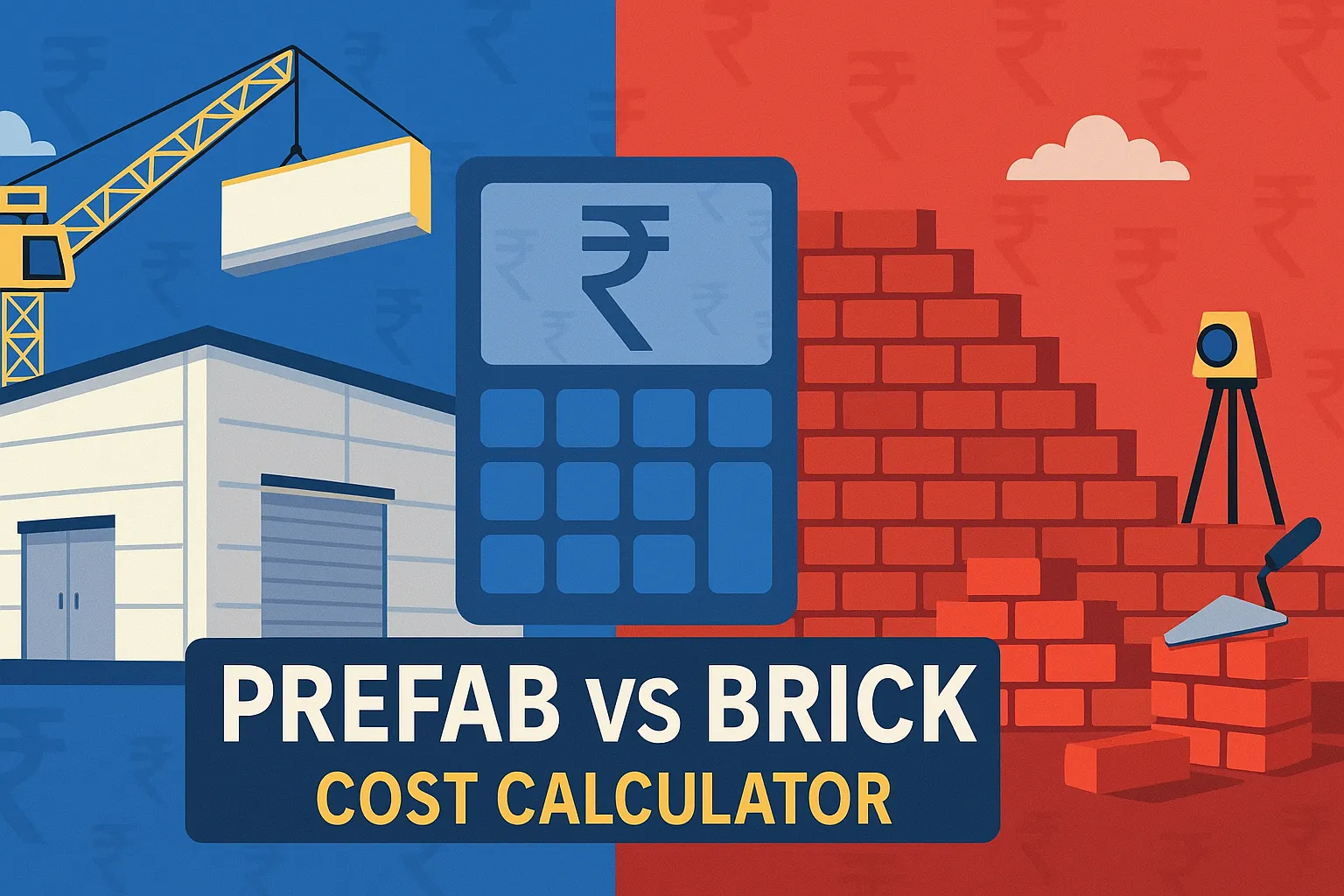

Prefabricated Components: HPCC components are manufactured off-site, allowing for parallel construction activities.

Shorter Project Timelines: This results in faster project completion, reducing labor and rental costs.

2. Cost Savings & ROI

Reduced Material Waste: HPCC’s precise manufacturing minimizes waste, lowering costs.

Lower Operating Costs: HPCC structures improve energy efficiency, cutting heating and cooling expenses.

3. Enhanced Worker Safety

Factory-Based Assembly: Most of the construction work happens in controlled factory environments, reducing on-site hazards.

4. Environmental Sustainability

Lower Carbon Footprint: HPCC’s lightweight materials reduce the use of resource-intensive materials like concrete and steel.

Energy-Efficient Design: The superior insulation properties reduce energy consumption, contributing to sustainability goals.

Versatile Applications of HPCC Technology

HPCC is a highly adaptable construction method suited for various industries:

1. Industrial and Warehouse Buildings

Fast-Track Construction: Ideal for logistics hubs, storage facilities, and manufacturing plants.

Superior Insulation: Keeps storage areas at optimal temperatures.

2. Commercial and Retail Spaces

Restaurants, Food Courts, and Service Stations: HPCC allows businesses to open faster and maintain consistent aesthetics across multiple locations.

3. Educational and Institutional Buildings

Office Buildings, Dormitories, and Hostels: Enhanced thermal and acoustic insulation improves occupant comfort.

4. Agricultural and Livestock Facilities

Poultry Farms, Livestock Sheds: Moisture-resistant and energy-efficient structures improve productivity.

The flexibility of HPCC makes it suitable for both new construction and expansion of existing buildings.

How HPCC is Manufactured: The Process Behind the Innovation

Understanding the HPCC manufacturing process helps explain why it outperforms traditional methods.

1. High-Precision Material Bonding

Patented Composite Technology: Specialized polymers and pre-coated steel are bonded at the molecular level.

Factory-Controlled Production: Ensures temperature, humidity, and pressure consistency for optimal material performance.

2. Customization for Project-Specific Needs

Adaptable Designs: HPCC components can be tailored to withstand high winds, seismic activity, or extreme weather conditions.

3. Seamless On-Site Assembly

Prefabricated Components: Designed for fast and secure assembly on-site.

Weather-Tight Structures: Joints are sealed using silicone applications for moisture resistance.

The streamlined production and installation process makes HPCC one of the fastest and most efficient construction methods available.

Why Choose HPCC for Your Next Project?

For developers and contractors looking for a high-performance, cost-effective, and sustainable building solution, HPCC offers:

- Superior Strength & Durability – Composite materials last longer with minimal maintenance.

- Energy Efficiency – Lower utility bills due to advanced insulation.

- Faster Construction – Prefabricated components reduce build time and labor costs.

- Customizable Design – Can be tailored for different industries and environmental conditions.

With the global construction composites market growing rapidly, HPCC is positioned as the future of commercial construction.

Comparing HPCC with Traditional Construction Methods

| Feature | HPCC | Traditional Steel/Concrete |

|---|---|---|

| Strength-to-Weight Ratio | High | Lower |

| Construction Time | Faster (Prefabricated) | Slower |

| Maintenance | Low | High (Corrosion, Wear) |

| Energy Efficiency | Excellent Insulation | Lower Insulation |

| Environmental Impact | Reduced Carbon Footprint | High Resource Consumption |

Conclusion: The Future of Commercial Construction with HPCC

High-Performance Composite Construction (HPCC) is transforming the construction industry by offering stronger, more efficient, and more sustainable building solutions.

As builders, developers, and business owners look for cost-effective and high-performing construction methods, HPCC presents an ideal choice.

With its rapid adoption across multiple sectors and the market’s continued growth, HPCC represents the future of commercial and industrial construction.

Explore HPCC for your next project and build with innovation, efficiency, and sustainability.