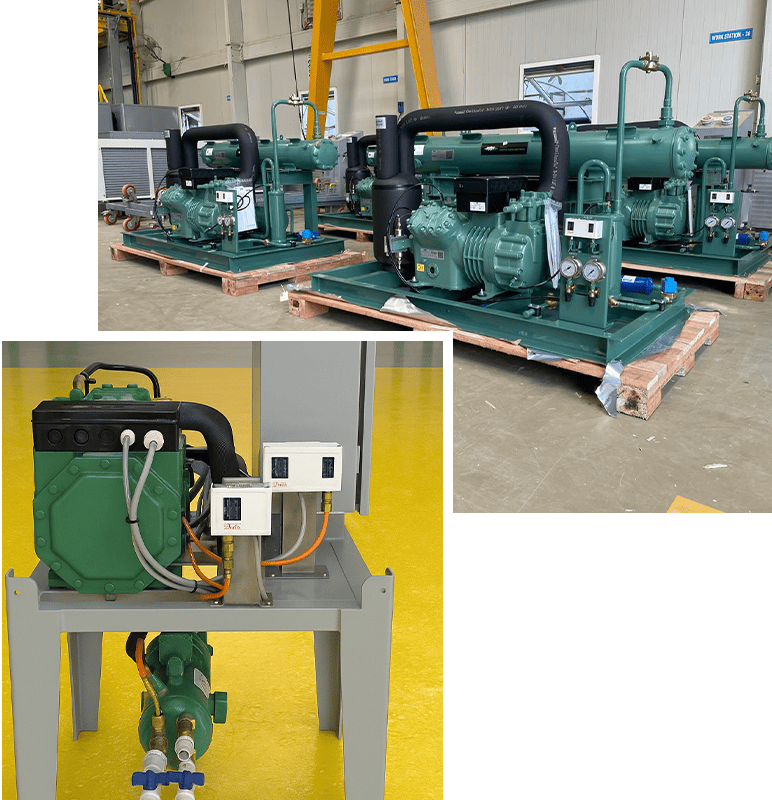

Cold chain infrastructure is the backbone of food safety, healthcare, retail, and industrial applications. At Rinac, we recognize that every business has unique requirements, which is why our refrigeration solutions are custom-designed for efficiency, sustainability, and reliability. From small commercial cold rooms to large industrial plants, our systems combine the right refrigerant technology—Ammonia or Freon—with the most suitable condenser type—air-cooled or water-cooled—to deliver optimum results.